The 3D Digital Image Correlation (DIC Q 480) System Q 480 is a fully portable optical measuring instrument for true full field, non-contact, three-dimensional analysis of displacements and strains on large industrial components and structures.

It is aimed at the industrial user requiring an out-of-the-box solution for deformation and strain measurements on large structures where data from many measurement locations is required.

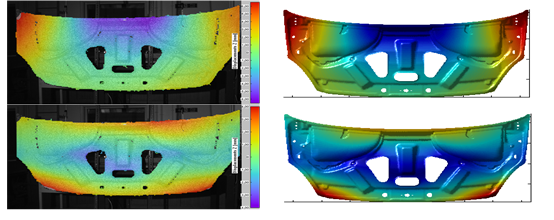

The DIC Q 480 system is an out-of-the-box ‘point and shoot’ concept with no calibration or setup. The DIC Q 480 has been adapted to suit industrial use on large structures. An almost unlimited number of reference images can be taken across the structure before the loading is applied. When revisiting each measurement location to acquire the second image, the system is repositioned using a novel hardware and software repositioning solution to minimize the rigid body motion, the strain field can be instantly seen.

The fixed design of the sensor means that the system does not require any setup or calibration like standard DIC systems. The integrated sensor head contains 2 CCD cameras, a smaller version of Dantec’s unique HILIS light source, repositioning laser pointers and control buttons. An option of a second remote touch screen improves usability in confined testing environments.

The DIC Q 480 runs on Dantec’s standard Istra4D software. The repositioning feature guides the user to the correct position where the difference between the final loaded image and the reference image is minimized. Once this position has been found, the displacement or strain results automatically appear overlaid on the live image and the user is free to save this image and move on.

The electronics and laptop are integrated in a robust Peli case for portability and to match the typical testing environment.

Open source format HDF5 – Istra4D stores all measured data in HDF5 format, which could be read di-rectly by e.g. MATLAB, Scilab.

Support Validation of FEM Simulations with e.g. HDF5 export or ANSYS plugin