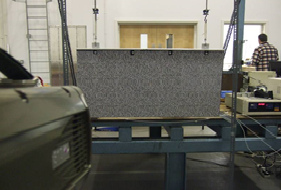

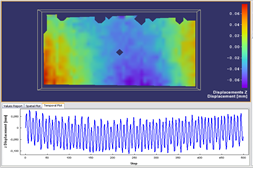

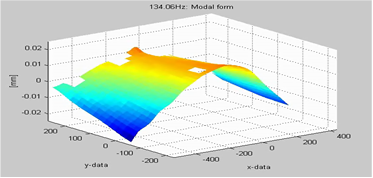

The 3D High-Speed Image Correlation System DIC Q 450 allows the full-field, non-contact and three-dimensional dynamic measurement of shape, displacements and strains on components and structures made from almost any material based on the digital image correlation technique. The DIC Q 450 system is designed for full-field vibration analysis and high speed transient events. E.g. ballistic testing, fracture mechanics, shock excitations, the Hopkinson Bar test or Impact Testing.

Its flexible design opens a wide range of applications from microscopic investigations on microelectronic or biomedical materials up to large scale measurements of aerospace, automotive, marine and railway components.

The system uniquely combines the high spatial resolution of full-field optical measurements with high temporal resolution. The dynamic range is from static to more than 100,000 Hz, with the capability to measure displacements from the micron to meter range. The resolution is typically around 1 micron and 0.01% strain. The system can be used for objects of any size by simply changing the optical lenses. Various extensions and application accessories allow the easy use of the Digital 3D-Correlation System DIC Q 450 in different experiments.

All system parameters are determined by a fast and easy calibration procedure – a very practical and simple process by positioning a calibration plate in front of the cameras. The achieved calibration accuracy is displayed online after the calibration.