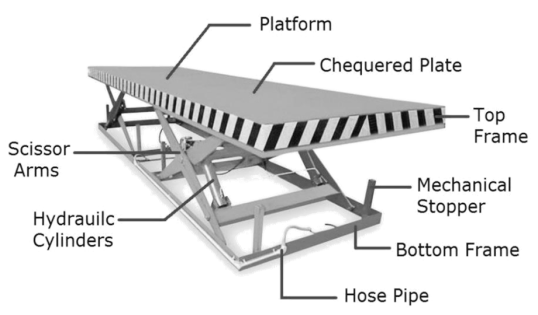

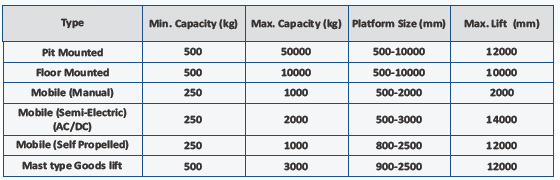

Scissor Lift

Scissor lift is a type of handling equipment used for heavy vertical lifting. They have a flat platform beneath which linked folded supports in criss–cross design known as the pantograph is attached. This pantograph extends vertically to lift the platform. Scissor Lifts are one of the popular equipment for material handling in the Indian industry and are being used for variety of applications. A specially designed and equipped scissor lift enhances the quality of logistic infrastructure and improves the facility’s competitiveness. These Scissor Lifts, available in wide ranges with various options, provide optimum solution to lift materials up to comfortable working heights with least worker fatigue and physical strain.

Key features of scissor lifts:

- Scissor lifts are mostly used in industries to lift people / workers. While lifting loads, it has to be assisted by people to unload the loads. The platform serves only vertical lifting

- Scissor lifts also serve as a worktable to position heavy bulk work pieces for machining operations.

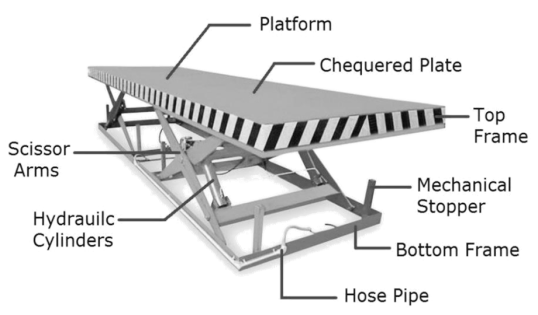

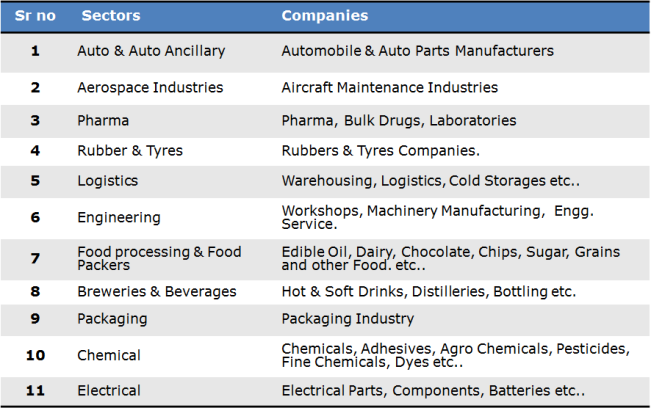

Applications Overview

- Loading & Unloading of Materials

- In feeding of material for processing, (i.e. metal, (sheet & products) MDF panels, lumber, cardboard, paper, and plastic products)

- Out feeds of material for stacking and palletizing

- Order picking distribution centers

- Positioning work for assembly, maintenance & processing

- Transferring material, at machine height & conveyor processing

- Loading docks

- Freight Lifts mezzanines, between levels

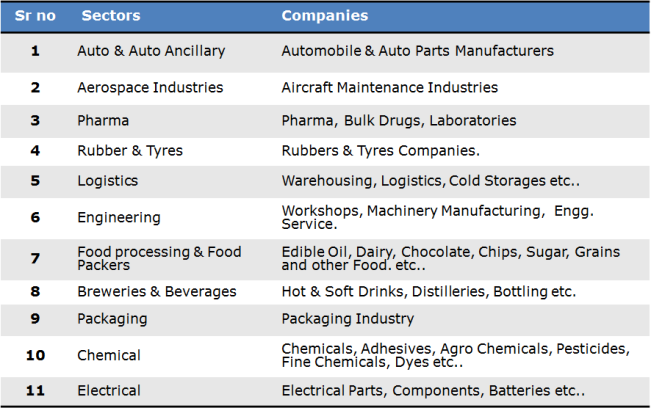

Jost’s Range of Scissor Lift

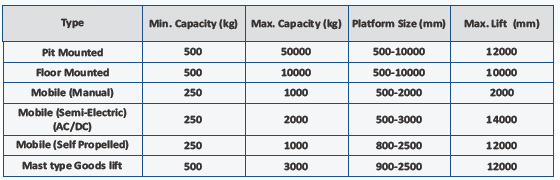

Jost’s range of scissor lifts are used for multiple purposes across industries. They come in load capacities Capacity from 500 kg to 50000 kg and can lift to heights of Lift heights upto 12 metres. Josts also offers customised solutions as per customer requests. More importantly the chequered platform with anti-skid feature provides safety of the operator

Types:

Pit Mounted Scissor Lifts

- Ideal for loading / unloading, production and material shifting applications

- Used where height difference is beyond the range of Dock Levellers.

- Capacity from 0.5 ton to 50 tonnes. Lift heights up to 12 metres

- Available in variations of heavy duty and medium duty loads

Tandem Scissor Lifts

- Ideal for heavy duty Production shop and logistics applications

- Used for jobs that require long platform

- Capacities up to 20 tonnes. Lift heights up to 3.5 metres.

- Two or more scissor pairs in combination and operated by single hydraulic system

Floor Mounted Scissor Lifts

- Extensively used in light duty applications for lifting goods to various lift height

- Ideal for shop floor, assembly line and production line applications as worktables

- Capacity upto 10 tonnes. Lift heights up to 10 metres

Twin Scissor Lifts

- Ideally suited in assembly shop application for medium duty jobs

- Capacities up to 6 tonnes. Lift heights up to 3 metres

- Two scissor lifts in tandem operation co-ordinated by single hydraulic circuit

Semi-Electric Mobile Scissor Lifts

- Ideal for maintenance jobs as well as order picking applications

- Capacity up to 1ton; Lift heights up to 12 metres

- Easily towable either manually or by powered vehicles (depends upon capacity)

- Earth lock/out riggers arrangements for greater Stability

- Available in AC and DC version

Self-Propelled Scissor Lifts

- Ideal for Maintenance purpose and Order Picking jobs

- Capacity up to 1 ton; Lift heights up to 8 metres.

- Driven by AC / DC motor and MOSFET controller

- These machines can be operated from lift platform top

- Quiter, cleaner operation for a variety of environments

- Narrow width fits most standard doorways and tight aisles

Vehicle Mounted Scissor Lifts

- Ideal for material shifting at various floor heights site

- Capacity up to 3 tonnes; Lift heights up to 12 metres

- Available in variations of pedestrian operated or ride-on models with Jost’s trucks

Electro Hydraulic Goods Lifts (Mast Lifts)

- Ideal for material shifting at various floor heights site

- Capacity up to 3 tonnes. Lift heights up to 12 metres

- Available based on application, in single or double mast construction

- Customised solutions available as per site application

Standard Features

- Josts scissor lifts are manufactured with ISMC Top & Bottom Frames to withstand high bending stresses

- Rectangular tubular sections which ensures less wear & tear of pins (as gets more surface area for rotation ) .

- Rectangular tubular sections which ensures less wear & tear of pins (as gets more surface area for rotation )

- Parker / Soni make hoses and hose fittings

- Hose burst valve ensures safety in case of hydraulic failure

Optional Feature

- Detachable / Drop down railings / Foldable Railings

- Guide rails (For high rise pit mounted / stationary lifts)

- Collapsible doors

- Door interlocking ( Electromechanical)

- Bellows

- Rolling shutters

- Roller Bed on top platform

- Audio siren

- Revolving lamp

- Access Ramp

- Ladder ( To access the platform in closed condition)

Key Performance Characteristics

- Uniformly Distributed Load

- Lifting / Lowering speed

- Low Platform entry height ( Closed height )

- Side Stabilizers for mobile scissor lifts ( Earth Locks )

- The ability to drive at full elevation in case of self propelled scissor lift.

- Travel speed in case of self propelled scissor lift.

- Clarity on Open height vs. Lift height.

- Loading applications (which kind of MHE going to be used and the weight of the same considered or not)

Successful Case Studies

Case Study 1

Customer Objective was to load the heavy machinery onto the container for shipment. Specific Challenge was that the Height of the loading bay was fixed and lots of heavy machinery were required to load onto the container. Further, As the weight was too high, Dock leveller was unable to fulfill this application. Team Jost’s studied the applications and suggested Pit Mounted heavy duty Scissor Lift. With Pit Mounted heavy duty Scissor Lift, the entire load of machine was raised up to the container Dock Leveller height. Due to this arrangement, the running machine was then easily able to move from the platform of the Scissor Lift to the inside of container. Team Jost’s had done the thorough inspection of final products before Delivering to customer. As a Result Loading bay preparation cost was reduced and Successful, safe and reliable loading of Machinery into the container turned possible.

Case Study 2

Customer Objective was to Replace Electric Hoist type with Hydraulic type for G+3 operation. Specific Challenge was that the Civil shaft was already been constructed, so the challenge was to design cut to cut platform size & bolted mast section to ease the installation. Team Josts studied the application and suggested Double Mast Goods Lift for G+2 Operation. Due to continuous operation, Team Josts suggested Hydraulic type over electric hoist type, as less maintenance requires in hydraulic type. Goods Lift was successfully installed at customer premises & was running with G+3 Operation with high speed approx. 8-10 m/min

Jost’s Available Capacity Range

26/10/2023 sumitajmera |

Josts Blogs