Aerial Work Platform

22 Dec 2023

4-wheel platform trucks are multi-purpose vehicles used for material transport and also lifting operations. 4-wheel platform trucks are highly customisable and hence it serves many purposes in industries.

The Jost’s Four Wheel Industrial Platform Truck type, Jotruk is medium and heavy duty material handling equipment used for the carrying the loads from 2,000 to 4,000 kg. These industrial platform trucks enable easy and long distance transportation of bulk and non-palletised load over long distances on asphalt or concrete road. These industrial platform trucks are available with the versions of AC and DC drives. The Jost’s platform trucks with AC technology provides additional advantage of reduced maintenance, improved power utilisation and improved battery life.

The four wheel industrial platform trucks are ideal for use in inter-plant transportation, factories, warehouses, defense units, railway workshops, airports, power plants and large processing units. Jost’s leads the way with tough, dependable industrial platform trucks

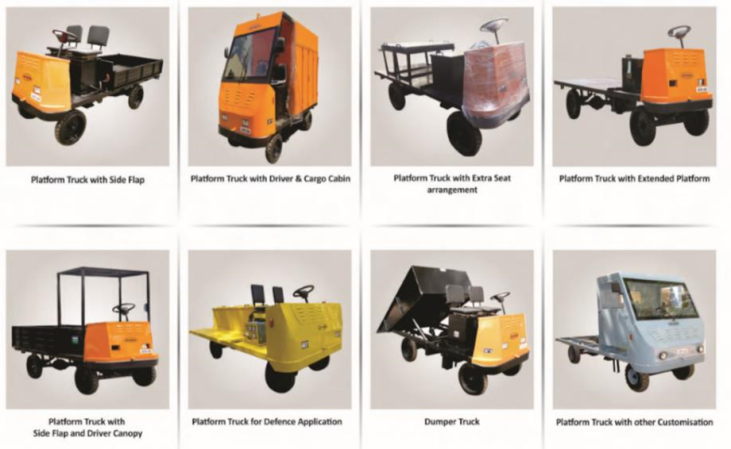

The truck comes with head, tail, brake light and horn as as standard.The truck can be provided with revolving lights/flashing lights , reverse buzzer, side indicators, canopy, operator cabin, side flaps, scissor lift platforms as an option.

Josts provides various customised solution as per project and application requirement across various industries

Application : Material, component inter-plant transportation. Rubber sheet to eliminate the jerk to safeguard their valuable instruments being transported

Application : Shifting of component, parts, loose material., shifting of boxes form production area to store area.

Application : Shifting / movement of spare bins.

Application : Standard platform truck application. When not used for material transportation, extra seat arrangement done for passenger movement inside the plant

Application : Shifting of Heavy material, loose & long material, boxes, large size material in inter-plant movement.

Application : To handle and shift component items and provide protection to operator from weather conditions & material from falling

Application : To handle and shift nitrogen gas cylinder for filling in aircraft wheels. Additionally crane mounted by customer for their application.

Application : For collection and shifting scrap material from machine shop

Application : 2 ton Jotruk without platform, where customer mounted their unit in platform area

Application : Platform Truck used for fire safety application

Customer Objective was that Wet mass of medicinal herbs was required to be handled and transferred from one process area to another and was further required to dump into reservoir, with high productivity

Specific Challenge was that This wet mass was required to be fill in various drums and was later on required to transport into reservoir area (agitator) and dumped into it manually.

In order to provide optimum solution, Team Josts studied the application and suggested to use 4-wheeler Dumper Platform Truck, considering floor condition and stability aspect of the dumper. With this the operation became easier and Productivity was also increased

Results

1.Overall safety was increased

2.Customer was successfully able to shift various components, parts and loose Material without any Material loss due to Slippery.

Sector– Plastic Component Manufacturing

Product Offered- Customised Platform Truck with Side Flaps

Customer Objective was to effectively manage the material shifting without any slippage

Specific Challenge was that Earlier before reaching Jost’s, customer was facing the material slipping issues while moving material from one place to another. Due to this customer was facing Loss of Material and was facing Safety Problems.

In order to provide optimum , Solution Team Josts had studied the application and suggested Customised Platform Truck with side Flaps.

Results

1.Instead of manually carrying 100 Kg drums number of times, a single platform truck was then started carrying 2000 kg load at a time, in a single transfer, thus increased overall Productivity.

2.Because Battery operated dumper was used, there was no pollution.

3.Time required to transfer complete load was reduced from 1 hour to 5 minutes.

4.Loading time was also reduced from 1 hour to 8 minutes, because of direct raising of dumper end by hydraulic power.

5.Area remained clean.

6.The same equipment could be used for transfer of herbal shrubs within the plant.

Sector- Engineering

Product Offered -4-wheeler Dumper Platform Truck

08/11/2023 sumitajmera | Josts Blogs