Aerial Work Platform

22 Dec 2023

Racking systems is probably, the most fundamental element that one can come across in warehouses. With the volume of goods moving across the value chain increasing day by day, racking systems play a pivotal role in warehousing and logistics operations.

Racking systems enable you to store goods vertically, with pallets placed one above the other, thus properly utilizing the limited warehouse space.

With a suitable racking system in place, managers can maximize space and optimize the warehouse for easy order picking and storage. Thus, one can summarize that racking systems offer the following advantages:

Before choosing the racking systems, one needs to consider the following factors:

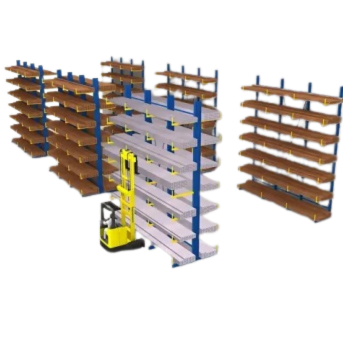

We at Jost’s have designed the Jorack range of racking systems for both heavy-duty and light-duty applications. We also provide specialized Cantilever and Drive-in racking systems for industries. The rack heights range from 3 metres to 17 metres and load capacities ranging from 500 kg to 1500kg per level.

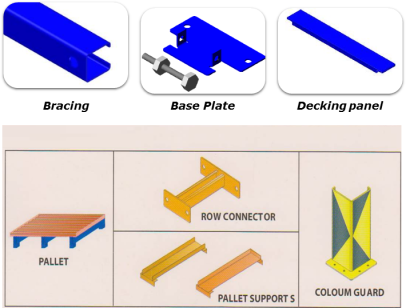

Jost’s provide additional accessories as per requirement

Customer wanted to effectively managed the Raw Material Storage at Warehouse. Earlier customer was stacking the pump sheet one above the other up to 3-meter height (block stacking). As because the pulp used to come in cut sheets, so it was scrapping and palletizing. Due to high production, customer was required to stock large number of pallets in warehouses. Team Jost’s had studied the applications and suggested using Racking System up to ground plus 6 levels along with Jost’s Reach Truck. As a result

Customer had Caged Pallets. They had 11 meters of height available with them. They wanted to utilize their entire full space available. A common racking system was required to accommodate all the Cages of different sizes at a place. Further, customers wanted to use an Articulated forklift instead of a Normal forklift to save more space. Jost’s Team studied the specification and suggested a Heavy Duty Shelving Racking System of G+5. It was provided with 3 MT Capacity per level. It had a minimum aisle width which enabled them to use the articulated forklift. As a result-1.customer was able to utilize full vertical height 2.storage capacity was also increased 3. The customer was able to use an articulated forklift

The customer was looking for an optimized storage solution that enabled them to get the maximum gain out of the available space. The customer was facing trouble with their safety requirement and was not able to utilize their available usable space. Team Josts studied the applications and suggested a Powder-coated Mezzanine floor Racking System. Josts provided it with 1.2 MT/sq.mtr capacity along with all the accessories and safety features. As a result, 1.Customer was able to use full vertical height space 2.customer had almost doubled the available space

30/06/2023 sumitajmera | Josts Blogs